What is Hindsight? It’s the ability or opportunity to understand and judge an event or experience after it has occurred. So…. because of our Thousands and Thousands of inspections, the application of Previous Hindsight coupled with Experience and Education during a Building and Home Inspection ultimately creates 20/20 observations with Foresight. The most important aspect of our practice is “Analytics”, or in other words, giving accurate observations to form accurate conclusions. These are the strengths that Benefit our clients.

TYPES OF FLAT ROOFS

EPDM ROOFING

Water ponding on upper flat roof but not adjacent lower roof(s)

After reviewing this roof and structure further, it was apparent the framing was sagging at the center of this roof allowing water to pond while adjacent roofs were draining properly.

As a result, this roof will need repairs to the substrate structure before a new roof material can be installed. There are other approaches to draining this flat roof such as a solar pump, which I classify as a temporary “fix”, however, I can not confirm its volume rating or effectiveness. If you would like to read more about it visit solarroofpumps.com

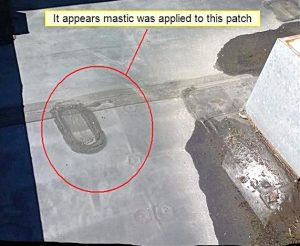

Here is another tip; Presuming it is an EPDM material, when you see patches on the roof and they appear to be tarred / mastic covered, that would be a no…no. Tar or Mastics do not adhere well to EPDM roofs. Please review the following photo:

The Mastic Here Already Started Cracking

Please note: There are other materials such (Polysobutylene-PIB) that appear to be EPDM material whereby patches will adhere well using Mastic/Tar

ROLLED ROOFING MEMBRANES

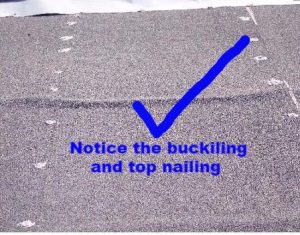

Rolled roofing is very common and does have a shorter lifespan than other types of materials and applications. The manufacturers’ may say it has a ten year plus or minus lifespan, but what’s more important to me is the condition when I review the material. For example; is it face nailed, are the seams open, does the material still have a granular surface, is there buckling or wrinkling, is it cracked….I think we all get the picture. Since we’re talking about pictures, take a look at the following photos to get an idea of what I am talking about:

Buckled roofing can cause premature failure and top nailing will cause leaks.

Both roofs in this photo look great to me!

BUILT UP ROOFING MATERIALS

Now..here are some pictures of a local commercial building’s roof where I was conducting a Full Inspection and Phase 1 Review. If you look at the details in the picture, my first impression was that this roof needs to be replaced immediately. Some localized areas exhibits cracks, alligatoring, etc.

So..what was the overall conclusion ?? The advantage I have over others is that I’ve been Building and Inspecting for many years now and have more field, book knowledge and contractor resources than most. In this this case I have a family member who only installs commercial roofs, So, I made a few calls and sent a few pictures to confirm my inspection observations. My final conclusion was that this roof exhibits some alligatoring and cracks in localized areas but the remainder of the roof only exhibits visibly worn protective coatings and minor damage. Therefore, I suggested either a new roof, which would be very expensive, or to conduct maintenance procedures immediately. Based on the feedback I received from my research and resources all agreed with my analysis whereby maintenance on this roof would be significantly less costly and could extend the life of this roof for many years.

DO’S AND DON’TS OF FLAT ROOF MATERIAL APPLICATION

For now let’s discuss Don’ts on flat roofs!

Do Not Use three tab or architectural roof shingles on a flat roofs. Take a look below at some pictures I took and what the results were using the wrong roofing material on this flat roof.

Flat Roof Using Architectural Shingles

Leaks Resulting Inside Garage As A Result Of Applying Architectural Shingles On A Flat Roof

Remember, a flat roof covering needs to be water tight. Typical roof shingles are not made for flat roof applications. If you refer to my previous article on Ice Damming, whereby the water builds-up and goes under the roof shingles, you will see that the same theory applies here.